Diaphragm walls have become a crucial engineering solution for stabilizing deep excavations and foundations in areas where high-water tables pose significant challenges. These walls are reinforced concrete structures built underground, acting as both retaining walls and waterproof barriers. They are especially effective in projects where construction needs to occur below the water table, such as tunnels, basements, and underground transportation systems.

In this blog, we will explore how diaphragm walls are designed to ensure stability in high-water table areas, the process involved in constructing them, and why they are essential for such challenging environments.

Understanding Diaphragm Walls

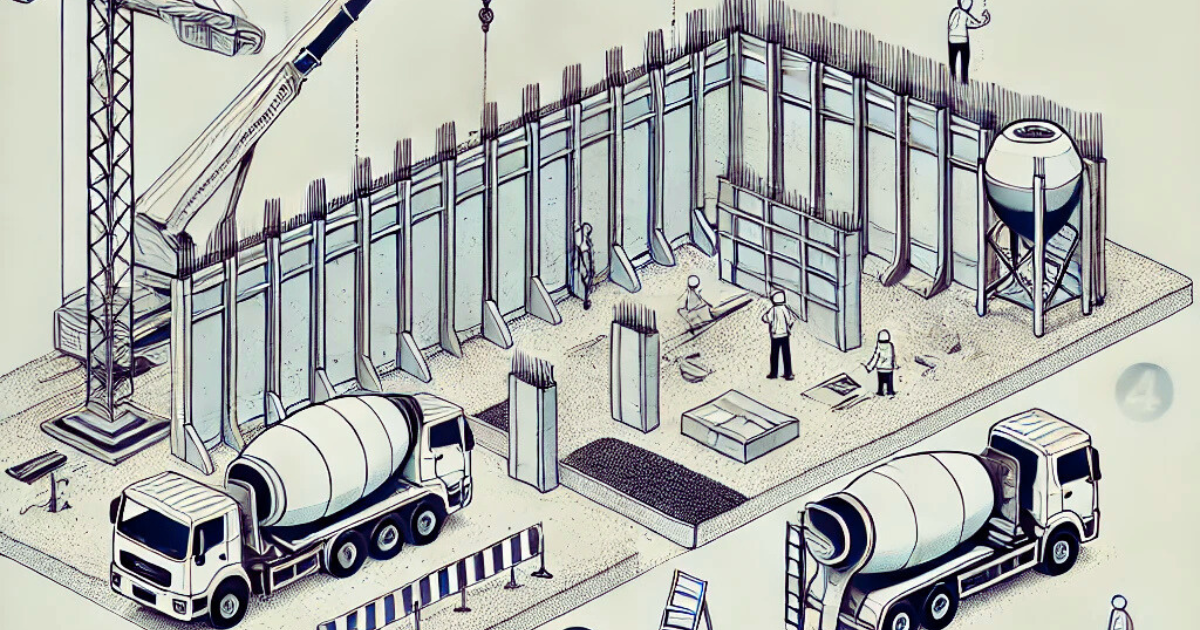

Diaphragm walls are built using specialized techniques to form continuous vertical barriers in the ground. These walls are constructed in situ (on-site) by excavating narrow trenches and filling them with reinforced concrete. The technique is ideal for urban and congested areas where deep excavations are necessary, but space constraints or ground conditions make traditional retaining walls inadequate.

The primary purpose of diaphragm walls is to provide structural support for deep excavations while preventing water infiltration from high-water table conditions. This makes them indispensable in large-scale infrastructure projects such as metro stations, underground parking, dams, and flood control systems.

High-Water Table Challenges

In areas with a high-water table, construction can be especially difficult due to several factors:

- Hydrostatic Pressure: The pressure exerted by groundwater can destabilize excavations, causing cave-ins or flooding.

- Soil Saturation: Waterlogged soils are prone to instability, making them difficult to excavate or support without the risk of collapse.

- Water Infiltration: When the water table is high, water can easily seep into excavations, leading to delays, increased costs, and compromised structural integrity.

These challenges necessitate robust solutions, and diaphragm walls are specifically designed to address them by creating a waterproof barrier that prevents groundwater from seeping into the construction site.

How Diaphragm Walls Work in High-Water Table Areas

1. Preventing Water Infiltration

One of the key benefits of diaphragm walls is their ability to prevent water infiltration in areas with a high-water table. During construction, the trench for the wall is often supported by a slurry, which is a thick liquid mixture (usually bentonite or polymer-based) that keeps the excavation open while preventing groundwater from flooding the trench.

Once the reinforcement cage is lowered into the trench, concrete is poured in, displacing the slurry and creating a solid, waterproof wall. The result is a continuous barrier that stops groundwater from entering the excavation site, ensuring a dry and stable environment for further construction.

2. Resisting Hydrostatic Pressure

Hydrostatic pressure from groundwater can exert significant forces on excavation walls, leading to potential structural failures. Diaphragm walls are specifically designed to resist this pressure. The reinforced concrete used in their construction provides the strength necessary to withstand the lateral forces exerted by the surrounding water-saturated soil.

Moreover, diaphragm walls can be built to great depths, ensuring that they remain stable even when the water table fluctuates. This makes them an ideal solution for projects located near rivers, lakes, or coastal regions where groundwater levels may be particularly high.

3. Maintaining Soil Stability

In areas with a high-water table, soil can become unstable due to saturation. This instability can lead to soil settlement, erosion, and the risk of excavation collapse. Diaphragm walls help stabilize the surrounding soil by acting as a retaining structure that prevents soil movement.

The walls transfer the load of the structure to deeper, more stable soil layers, allowing for safe construction in waterlogged environments. By providing lateral support, diaphragm walls ensure that the surrounding ground remains intact, reducing the risk of soil displacement or collapse during excavation.

4. Minimizing Environmental Impact

When working in areas with a high-water table, controlling groundwater flow is critical to avoid environmental disruptions. Diaphragm walls are an effective way to manage groundwater without resorting to extensive dewatering methods, which can have adverse effects on the local ecosystem. By acting as a waterproof barrier, these walls contain groundwater within the site, preventing contamination or alteration of surrounding water systems.

Additionally, by avoiding excessive dewatering, projects using diaphragm walls help maintain the natural balance of groundwater levels, which is essential for protecting nearby habitats and water sources.

5. Supporting Large-Scale Infrastructure Projects

Large-scale infrastructure projects, such as subway systems, underground parking facilities, and basements for skyscrapers, often require construction below the water table. Diaphragm walls provide the necessary structural integrity to handle the unique challenges posed by these environments.

For example, when constructing underground tunnels for subways, diaphragm walls can create a watertight environment that allows safe and efficient excavation. Without such walls, the risk of water intrusion and collapse would make these projects far more dangerous and costly.

Diaphragm Wall Construction Process

The construction of diaphragm walls involves several steps, each crucial for ensuring the stability and effectiveness of the wall, particularly in high-water table areas.

a. Site Investigation and Design

Before construction begins, a thorough site investigation is conducted to assess the soil conditions, groundwater levels, and the specific challenges of the project. This information is used to design the diaphragm wall, including its depth, thickness, and reinforcement requirements.

b. Trench Excavation

The trench for the diaphragm wall is excavated in sections, typically using a combination of mechanical and hydraulic excavation equipment. During excavation, slurry is introduced to the trench to support the walls and prevent water from seeping in.

c. Reinforcement Installation

Once the trench is excavated, a steel reinforcement cage is lowered into the trench to provide additional strength to the wall. The cage is typically prefabricated off-site to ensure precision and quality.

d. Concrete Pouring

After the reinforcement is in place, concrete is poured into the trench using tremie pipes, which allow the concrete to flow without displacing the reinforcement. As the concrete is poured, it displaces the slurry, creating a solid, continuous wall.

e. Curing and Waterproofing

Once the wall is completed, it is allowed to cure, ensuring maximum strength and durability. Depending on the project’s requirements, additional waterproofing treatments may be applied to enhance the wall’s resistance to groundwater infiltration.

Conclusion

In high-water table areas, diaphragm walls are a critical solution for ensuring stability and safety during construction. Their ability to prevent water infiltration, resist hydrostatic pressure, and stabilize saturated soils makes them an indispensable tool for large-scale infrastructure projects. From underground parking facilities to subway tunnels, diaphragm walls enable safe and efficient construction in challenging environments.

By investing in diaphragm wall construction, contractors can overcome the difficulties posed by high-water tables while minimizing environmental impact and ensuring long-term structural integrity.