YOUR TRUSTED INFRASTRUCTURE SOLUTION PROVIDER

100% Strength Guarantee With Amdavad’s No. 1 RMC

YOUR TRUSTED INFRASTRUCTURE SOLUTION PROVIDER

500+ Strong family and 100% Strength Guarantee!

1,000+

Projects

15,00,000+

Cubic Meter Concreting

BEST & TRUSTED PARTNER For Construction Projects

Residential, Commercial, Industrial Plants, Bridges, RCC Roads Construction.

14+ YEARS OF EXPERIENCE

10,000 Dreams of Families for their Homes/Offices Fulfilled.

Recent Updates

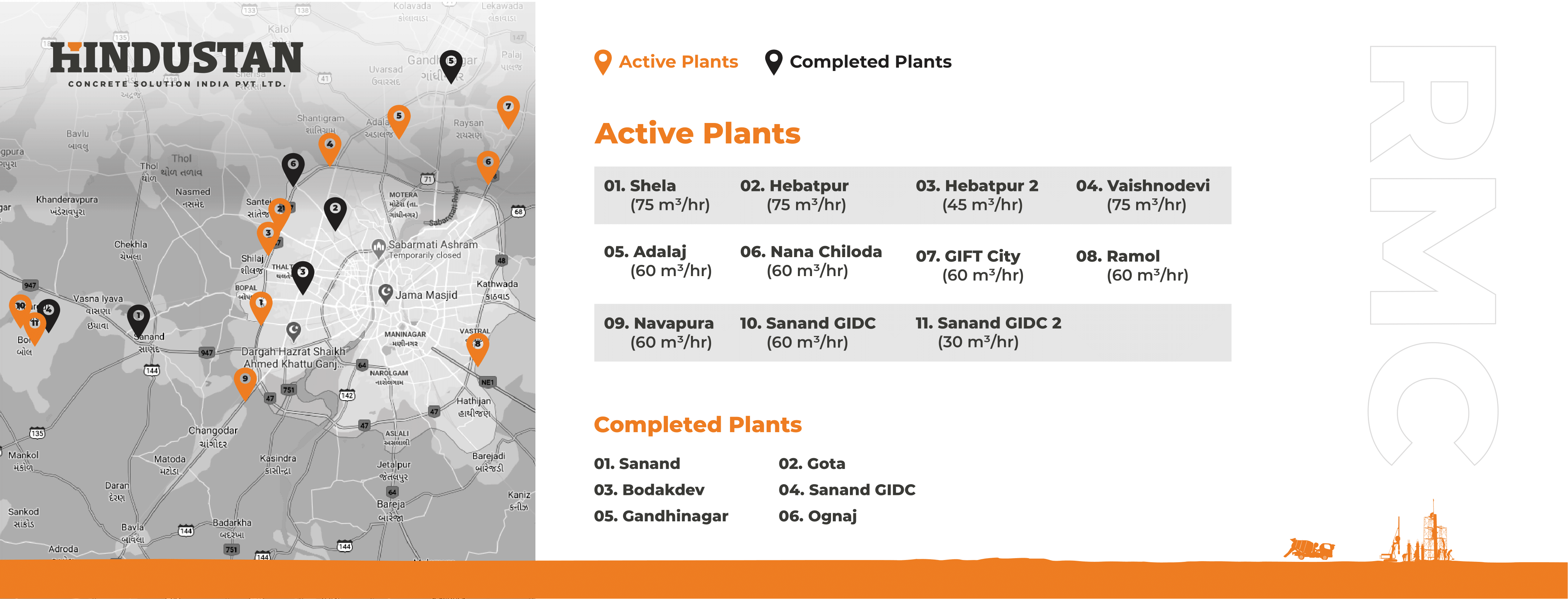

OUR RMC PLANTS

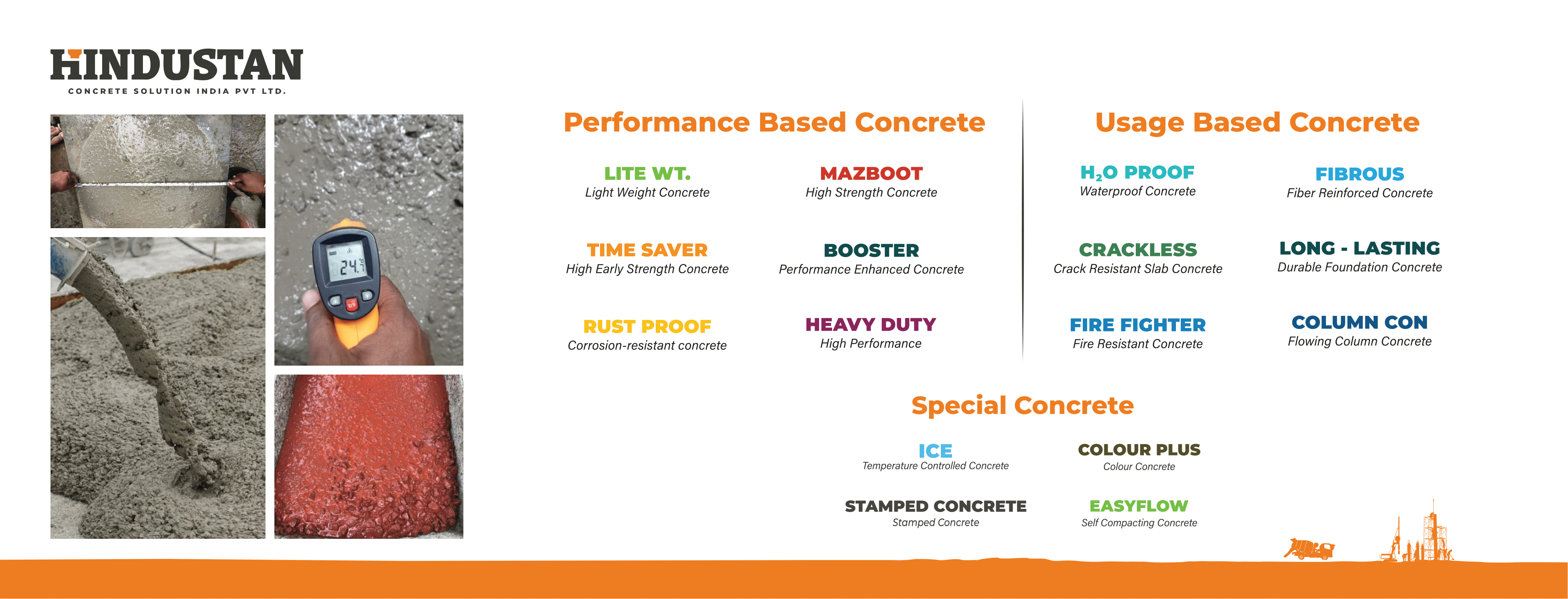

OUR SERVICES

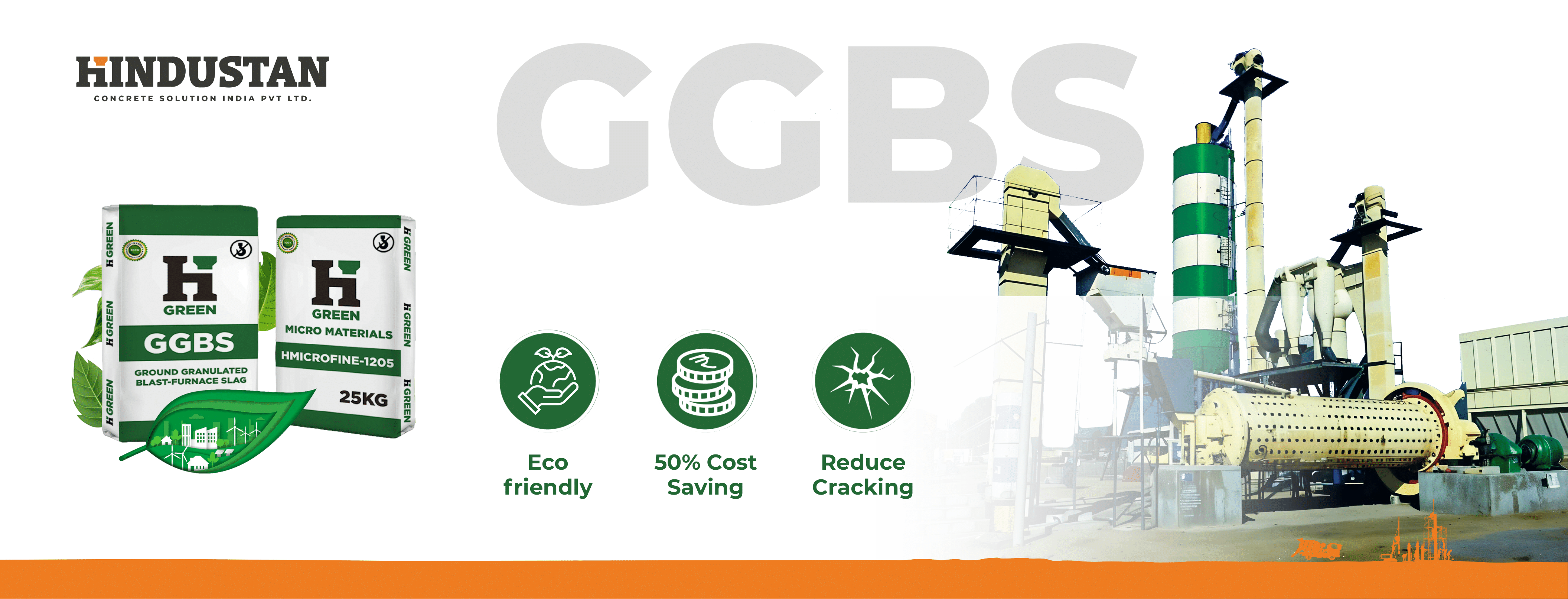

Hindustan Infrastructure Solution aims to deliver the best services for your construction project which stands stronger and longer in any adverse conditions.

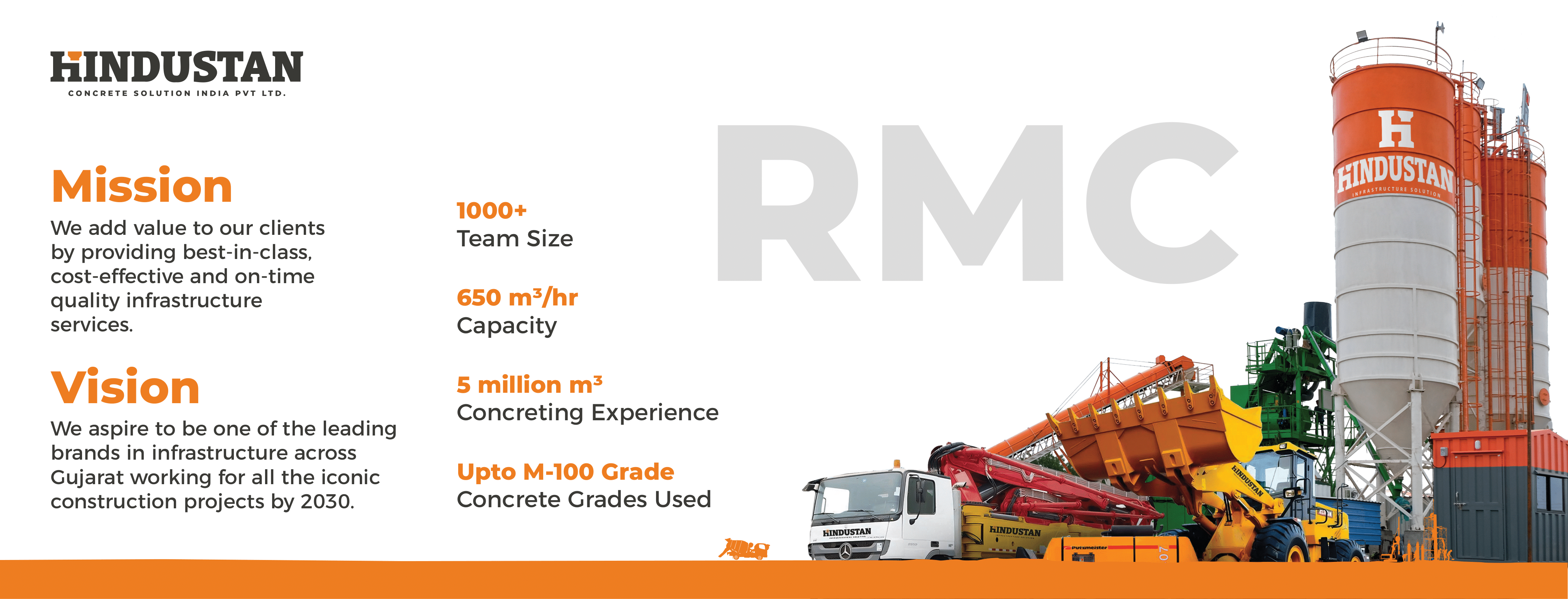

RMC

Manufacturing of Ready To Mix Concrete at our own plant for construction purposes.

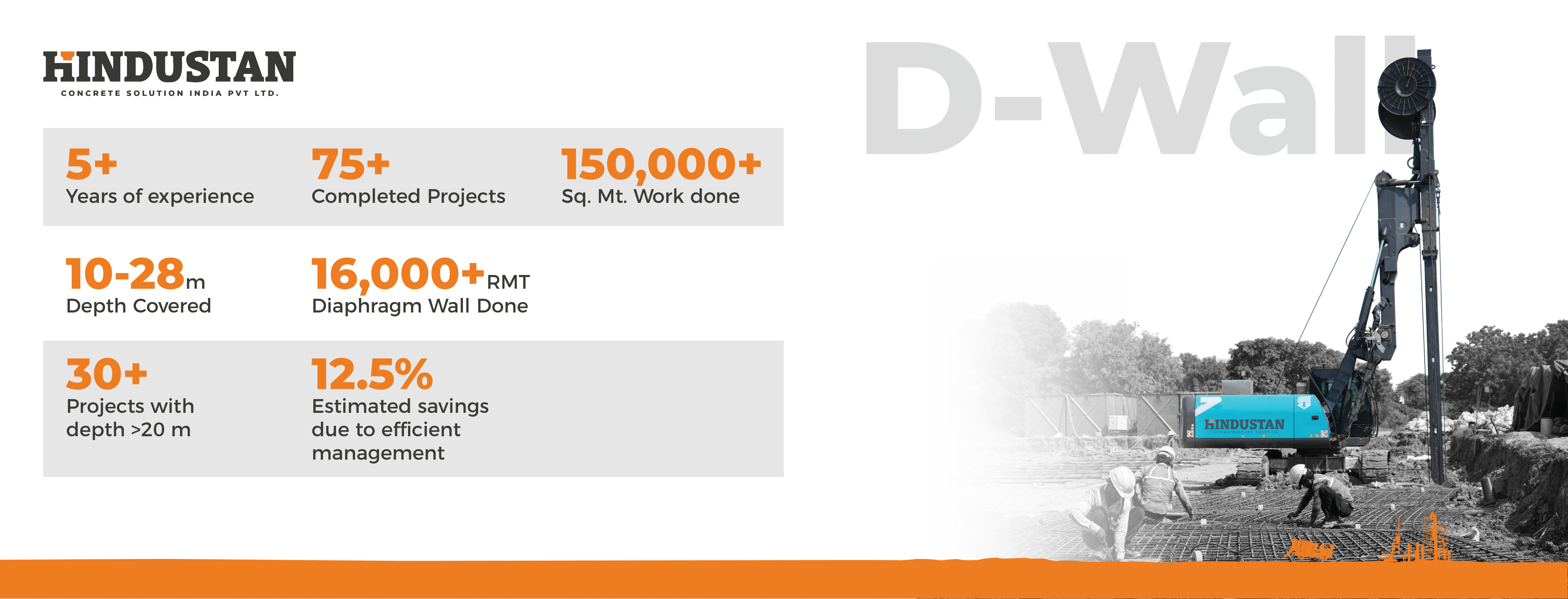

Diaphragm Wall Construction

Reinforced concrete structures built as retaining walls & underground foundations

Special Concrete

Securing objects usually resistant to screws or nails on materials such as concrete.

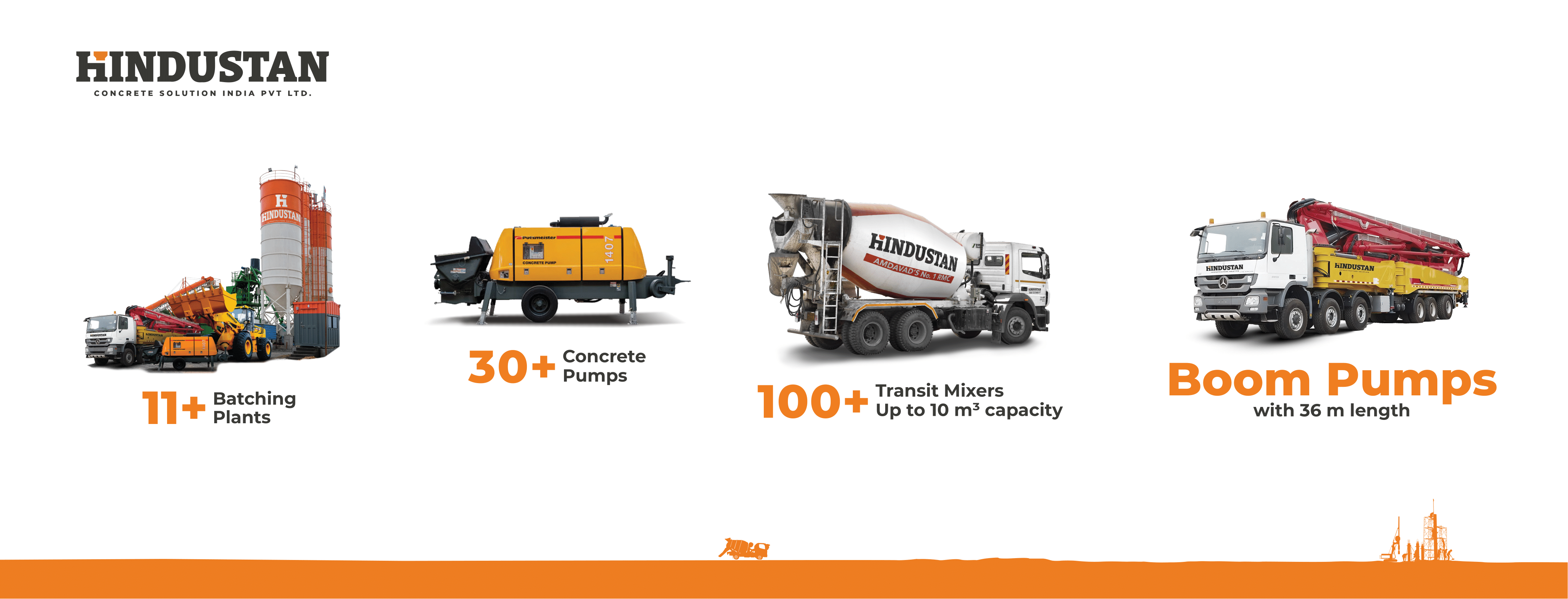

Equipment on Hire

We not only supply RMC but also support your concrete needs by renting out our infrastructure.

Stone Crushing

Backward Integration into stone crushing business under the name of New Rayka Stone LLP.

Turnkey Solution

We supply strength to your projects through 360-degree complete concrete solutions.

AMDAVAD'S NO. 1 RMC

Hindustan Infrastructure Solution understanding your every need is by your side to construct the impeccable projects that lasts longer than you expect.

Special RMC and D-Wall construction is what makes us Amdavad’s no. 1 RMC. We build the projects that are Strong has Strength, Support and are Solid to give you the best, when the foundation is strong the built-up is strong.

DIAPHRAGM WALL

A diaphragm wall is a structural concrete wall constructed in a deep trench excavation. It is a type of retaining wall that is used to build the foundation of the building. It is made panel by panel which are 3-7 meter long further making it a continuous wall. Diaphragm walls are often used for larger construction projects such as foundation walls, basement projects, underground railway projects etc.

Diaphragm walls from Hindustan are suitable for most subsoil and their installation generate only a small amount of vibration and noise, which increases their suitability for works carried out close to existing structures. We provide an explicit range of these walls so that you can find your suitable match in a suitable price.

OUR PROJECTS

Residential

Residential

Commercial

Commercial

from the very beginning for numerous commercial projects.

Industrial

Industrial

Roads & Bridges

Roads & Bridge

Others

Others

OUR LATEST NEWS & BLOGS

CLIENTS SHARING THEIR EXPERIENCES

TESTIMONIALS

LET'S GET IN TOUCH

- 7th Floor, Wing A, Swati Trinity, Sardar Patel Ring Rd, near Applewoods Township, near Shantipura Circle, Shela, Ahmedabad, Gujarat 380058

- 1800 569 9977

- info@hindustanrmc.com