In today’s world, sustainability is at the forefront of construction practices. As we strive to reduce our environmental impact, one of the key questions that arises is, “Can concrete be recycled?” Concrete is a vital material used in countless structures, from roads and bridges to buildings and pavements. Understanding whether concrete can be recycled and how it can be done effectively is crucial for anyone involved in construction or interested in sustainable practices.

Understanding Concrete and Its Importance

Concrete is composed of cement, water, and aggregates such as sand and gravel. It’s known for its strength, durability, and versatility, making it a staple in the construction industry. However, with the massive amounts of concrete used globally, it’s essential to consider its end-of-life management. This brings us to the question: Can concrete be recycled?

The Basics of Concrete Recycling

What Does Concrete Recycling Involve?

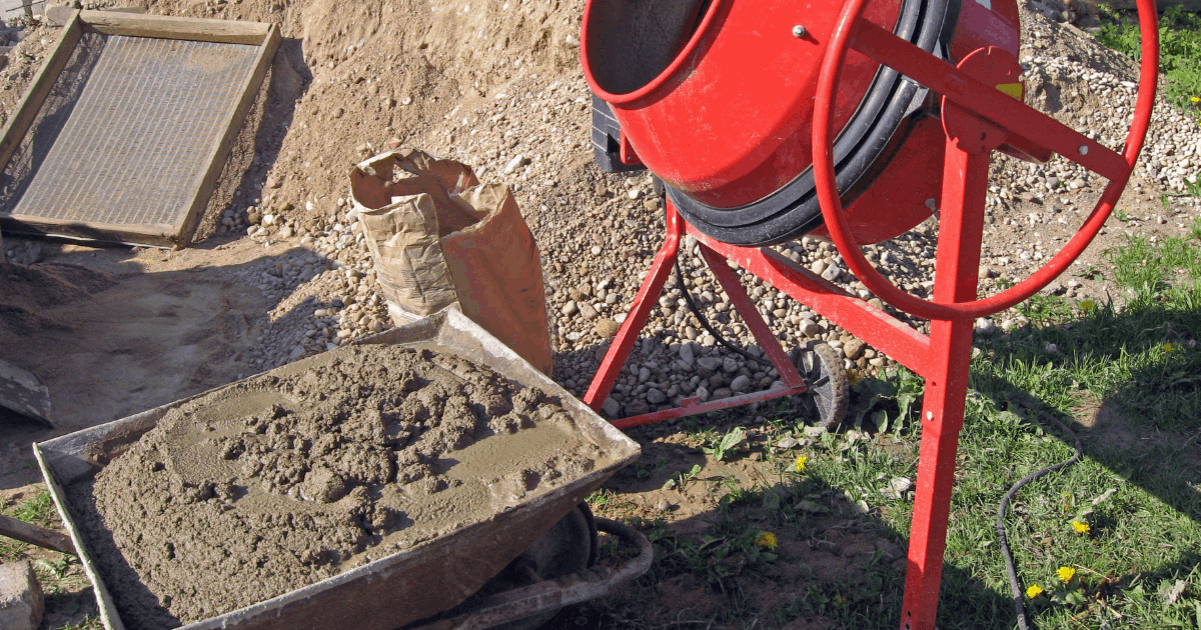

Concrete recycling involves the process of breaking down old concrete structures into smaller pieces and reusing these pieces in new construction projects. This process typically includes:

Collection and Transport: Demolished concrete is collected from construction or demolition sites and transported to a recycling facility.

Crushing: The concrete is then crushed into smaller, manageable pieces. This can be done using various types of crushers, such as jaw crushers or impact crushers.

Screening: The crushed concrete is screened to separate it into different sizes. This process ensures that the recycled concrete is sorted according to its intended use.

Reprocessing: In some cases, the recycled concrete is further processed to improve its quality or to produce specific grades of material.

Benefits of Recycling Concrete

Recycling concrete offers several advantages:

Reduces Landfill Waste: Recycling concrete helps divert waste from landfills, reducing the environmental impact of construction and demolition debris.

Conserves Natural Resources: By reusing concrete, we can conserve natural resources such as gravel and sand, which are used in the production of new concrete.

Lowers Carbon Footprint: The production of new concrete involves significant carbon emissions. Recycling concrete reduces the need for new cement and aggregates, thereby lowering the overall carbon footprint of construction projects.

Cost Savings: Using recycled concrete can be more cost-effective than using virgin materials, leading to potential savings in construction costs.

How Can Concrete Be Recycled?

Methods of Recycling Concrete

There are several methods to recycle concrete, each suitable for different types of projects and recycling needs. The main methods include:

Crushing and Reuse: The most common method, where concrete is crushed and reused as aggregate for new concrete or other construction applications.

Manufacturing Recycled Concrete Aggregate (RCA): Crushed concrete can be processed into recycled concrete aggregate, which can be used as a base material for roads, pavements, and other applications.

Recycling Concrete into New Products: Recycled concrete can be used to produce new products such as precast concrete blocks, tiles, and pavers.

Incorporating Recycled Concrete in Asphalt: Recycled concrete can be mixed with asphalt for use in road construction, providing a durable and sustainable alternative to traditional materials.

Considerations for Recycling Concrete

While recycling concrete has many benefits, it’s important to consider certain factors:

Quality Control: The quality of recycled concrete can vary depending on the source material and processing methods. It’s essential to ensure that the recycled concrete meets the required standards for its intended use.

Contamination: Concrete mixed with other materials, such as metals or wood, may be contaminated and require additional processing to remove impurities.

Structural Integrity: Recycled concrete used in structural applications must be tested to ensure it meets strength and durability requirements.

Can Concrete Be Recycled for All Types of Projects?

Applications of Recycled Concrete

Recycled concrete is versatile and can be used in various applications, including:

Road Base: Recycled concrete can be used as a base material for road construction, providing a stable and cost-effective foundation.

Pavements and Sidewalks: Recycled concrete can be used in the construction of pavements and sidewalks, offering a sustainable alternative to traditional materials.

Concrete Production: Recycled concrete aggregate can be incorporated into new concrete mixes, reducing the need for virgin materials.

Landscaping: Recycled concrete can be used in landscaping projects, such as retaining walls, garden beds, and decorative features.

Limitations and Challenges

While recycled concrete has many applications, there are limitations and challenges to consider:

Strength and Durability: Recycled concrete may not always match the strength and durability of virgin concrete. It’s crucial to assess the suitability of recycled concrete for specific applications.

Consistency: The quality of recycled concrete can vary, making it important to ensure consistent quality through proper processing and testing.

The Future of Concrete Recycling

Innovations and Advances

As the construction industry continues to focus on sustainability, innovations and advances in concrete recycling are emerging:

Advanced Crushing Technologies: New technologies are improving the efficiency and effectiveness of concrete crushing and processing.

Enhanced Quality Control: Improved methods for quality control and testing are helping to ensure that recycled concrete meets the required standards.

Increased Use of Recycled Concrete: The adoption of recycled concrete in various applications is expected to grow, driven by increasing awareness and demand for sustainable construction practices.

Promoting Concrete Recycling

To maximize the benefits of concrete recycling, it’s essential to promote and encourage its use. This can be achieved through:

Education and Awareness: Raising awareness about the benefits of concrete recycling and the importance of sustainable construction practices.

Regulations and Incentives: Implementing regulations and incentives to encourage the use of recycled concrete in construction projects.

Collaboration and Innovation: Collaborating with industry stakeholders to develop new technologies and techniques for concrete recycling.

Conclusion

The question, “Can concrete be recycled?” is met with a resounding yes. Concrete recycling is not only possible but also essential for promoting sustainability in the construction industry. By understanding the methods, benefits, and challenges of concrete recycling, we can make informed decisions that contribute to a more sustainable future. Embracing concrete recycling helps reduce waste, conserve natural resources, and lower the environmental impact of construction projects.

As the industry continues to innovate and improve recycling practices, the role of recycled concrete will become increasingly significant. By prioritizing concrete recycling, we can build a more sustainable and resilient future, one project at a time.