Concrete is one of the most widely used building materials in the world, essential for constructing buildings, roads, bridges, and various other structures. However, not all concrete is created equal. There are different types of concrete tailored for specific uses and applications. Two common types are ready mix concrete and normal concrete. Understanding the difference between ready mix concrete and normal concrete is crucial for construction professionals and anyone involved in building projects. This blog will explore these differences in detail.

Difference Between Ready Mix Concrete and Normal Concrete: What is Normal Concrete?

Normal concrete, often referred to as traditional or site-mixed concrete, is mixed on-site according to specific requirements. The basic components of normal concrete are cement, water, and aggregates (sand, gravel, or crushed stone). Sometimes, admixtures are added to modify the properties of the concrete.

Characteristics of Normal Concrete:

- On-site Mixing: The ingredients are mixed at the construction site, allowing for customization based on the specific needs of the project.

- Flexibility: Adjustments to the mix can be made on-site to suit weather conditions and specific structural requirements.

- Labor Intensive: Requires skilled labor to ensure the correct proportions and proper mixing technique.

- Quality Control: Quality can vary depending on the skill of the workers and the conditions under which the concrete is mixed and placed.

What is Ready Mix Concrete?

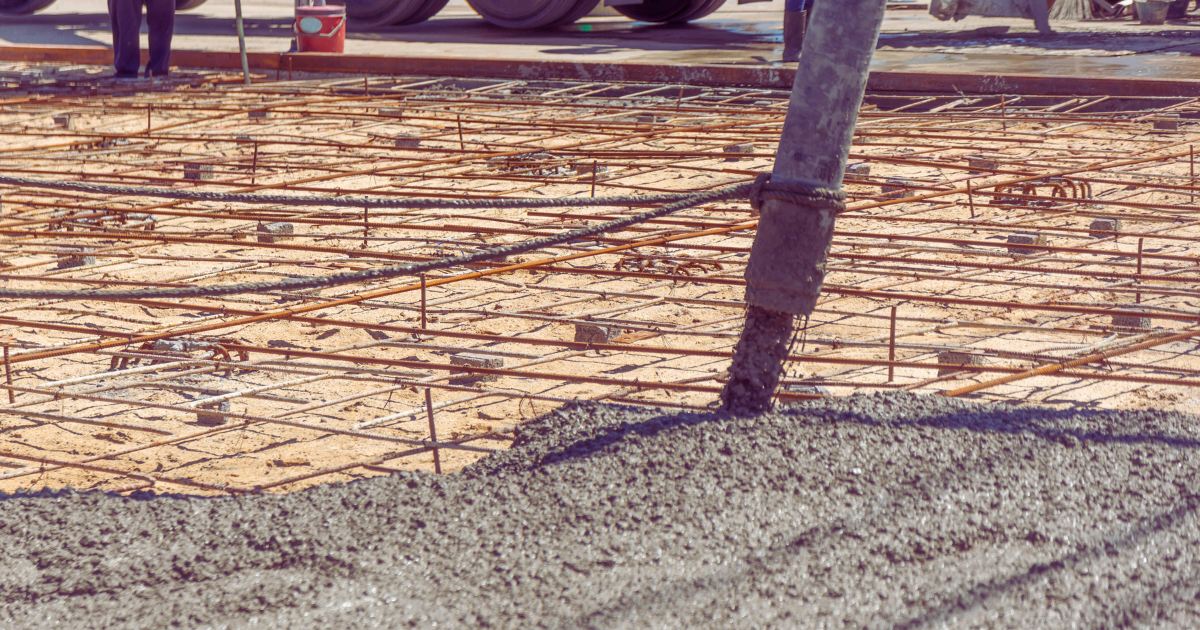

Ready mix concrete (RMC) is a type of concrete that is manufactured in a batch plant according to a set recipe, and then delivered to the construction site in a ready-to-use state. The process involves precise control of proportions and quality, ensuring a consistent and reliable product.

Characteristics of Ready Mix Concrete:

- Manufactured Off-Site: Mixed in a dedicated plant and transported to the construction site in mixer trucks.

- Consistency: Offers high consistency and uniformity due to controlled manufacturing conditions.

- Efficiency: Reduces time and labor on-site as the concrete is delivered ready to use.

- Quality Control: Rigorous quality control measures in place to ensure the concrete meets the required specifications.

The Key Difference Between Ready Mix Concrete and Normal Concrete

Understanding the key difference between ready mix concrete and normal concrete can help you choose the right type for your project. Here are some important distinctions:

1. Mixing Process:

- Ready Mix Concrete: Prepared in a controlled environment at a batching plant. This ensures precise and consistent mixing of the components.

- Normal Concrete: Mixed on-site, often resulting in variability in the mix due to manual mixing and environmental conditions.

2. Quality Control:

- Ready Mix Concrete: Subject to stringent quality control measures, including regular testing of raw materials and finished products. This guarantees a high-quality, reliable product.

- Normal Concrete: Quality can vary depending on the skill of the workers, the accuracy of measurements, and on-site conditions. Consistency may be harder to achieve.

3. Convenience:

- Ready Mix Concrete: Delivered to the site ready to use, saving time and reducing labor costs. Ideal for large projects requiring significant amounts of concrete.

- Normal Concrete: Requires on-site mixing, which can be time-consuming and labor-intensive. Better suited for smaller projects or situations where customization is necessary.

4. Cost:

- Ready Mix Concrete: Generally more expensive due to the costs associated with transportation and the precision of the manufacturing process. However, it can save money on labor and time.

- Normal Concrete: Typically less expensive in terms of material costs but can be more labor-intensive and time-consuming, potentially increasing overall project costs.

5. Environmental Impact:

- Ready Mix Concrete: Batch plants often have better access to quality raw materials and can implement recycling and waste reduction measures more effectively. The transportation of RMC, however, can contribute to carbon emissions.

- Normal Concrete: Mixing on-site can lead to wastage of materials and environmental degradation if not managed properly. However, it eliminates the need for transportation, reducing emissions associated with delivery.

6. Storage and Handling:

- Ready Mix Concrete: Requires careful handling during transportation to prevent segregation and maintain the mix’s consistency. Needs to be used within a specific time frame to avoid setting before placement.

- Normal Concrete: Mixed on-site as needed, reducing concerns about storage and transportation. However, it requires adequate facilities for storing raw materials.

Applications of Ready Mix Concrete vs. Normal Concrete

The choice between ready mix concrete and normal concrete often depends on the specific requirements of the project. Here are some typical applications for each type:

Ready Mix Concrete:

- Large-Scale Projects: High-rise buildings, bridges, dams, and large infrastructure projects benefit from the consistency and quality control of RMC.

- Time-Sensitive Projects: Projects requiring quick turnaround times, such as road repairs and emergency infrastructure works.

- Complex Mix Designs: Specialized concrete mixes, such as high-strength concrete, self-compacting concrete, and architectural concrete, are best produced in a controlled environment.

Normal Concrete:

- Small-Scale Projects: Residential construction, small commercial buildings, and minor renovations where on-site mixing is feasible.

- Custom Mix Requirements: Situations requiring specific adjustments to the mix based on immediate site conditions.

- Budget-Constrained Projects: Projects where cost savings on materials are crucial, and labor costs are lower.

Conclusion

Understanding the difference between ready mix concrete and normal concrete is essential for making informed decisions in construction projects. Ready mix concrete offers advantages in terms of quality, consistency, and efficiency, making it suitable for large-scale and time-sensitive projects. Normal concrete provides flexibility and cost savings for smaller projects and situations requiring on-site adjustments.

Choosing the right type of concrete depends on various factors, including project size, budget, timeline, and specific structural requirements. By considering these factors and the key differences between ready mix concrete and normal concrete, construction professionals can ensure the successful completion of their projects with the most appropriate and effective materials.